Across many modern water and HVAC systems, operators often compare the functions of an Intelligent Centrifugal Pump and a Pipeline Circulating Pump to decide which equipment better supports efficiency and infrastructure protection. With the development of permanent magnet motor technology, pipeline circulation pumps are offering new levels of performance that directly influence energy use, flow stability, and maintenance needs. Understanding why permanent magnet integration matters can help building managers, facility operators, and engineers make more informed choices for their systems.

Improving Energy Efficiency Through Motor Design

Permanent magnet motors are designed to reduce electrical losses that commonly occur in traditional induction motors. When applied to a pipeline circulating pump, this motor technology ensures that less energy is wasted during operation, particularly under partial load conditions. Since circulation pumps often run continuously in commercial and residential systems, the energy savings accumulate over time, lowering operating expenses. While intelligent centrifugal pumps also achieve energy optimization through variable frequency control, the permanent magnet motor provides inherent efficiency benefits even at steady circulation speeds.

Enhancing Flow Stability in Closed-Loop Systems

Pipeline circulating pumps are frequently used in heating and cooling loops, where steady water movement is essential to maintaining consistent temperatures. Permanent magnet technology improves torque control, allowing the pump to run smoothly with fewer speed variations. This translates into more stable flow, reducing the chances of uneven heating or cooling across different zones of a building. When combined with intelligent centrifugal pumps for pressure regulation, circulation pumps with permanent magnet motors strengthen overall system balance, ensuring both comfort and reduced mechanical stress.

Lowering Noise and Vibration Levels

A practical benefit of permanent magnet motors is their quieter and smoother operation compared with conventional designs. For commercial buildings, hotels, or residential complexes, reduced noise is an important factor in maintaining comfort. A pipeline circulating pump equipped with permanent magnet technology generates less vibration, which not only improves user experience but also decreases wear on connected pipes and joints. This quieter operation makes the technology suitable for environments where pumps run close to occupied spaces.

Reducing Maintenance Requirements

Because permanent magnet motors generate less heat and operate more efficiently, they place less stress on internal pump components. Bearings, seals, and impellers experience reduced wear when compared with pumps driven by conventional motors. For facility managers, this means fewer maintenance interventions and longer intervals between servicing. Over time, reduced maintenance translates into lower operational costs and less downtime. Intelligent centrifugal pumps often focus on adaptive operation, while pipeline circulating pumps with permanent magnet technology excel in continuous, low-maintenance performance.

Supporting Sustainability Goals in Building Operation

Energy efficiency is increasingly tied to sustainability objectives in modern commercial construction and facility management. A pipeline circulating pump that integrates permanent magnet motor technology directly supports these goals by cutting electricity consumption. Reduced energy use means fewer greenhouse gas emissions when electricity is sourced from conventional power plants. For buildings working toward energy certifications or environmental compliance, adopting pumps with permanent magnet motors provides measurable improvements in performance without sacrificing functionality.

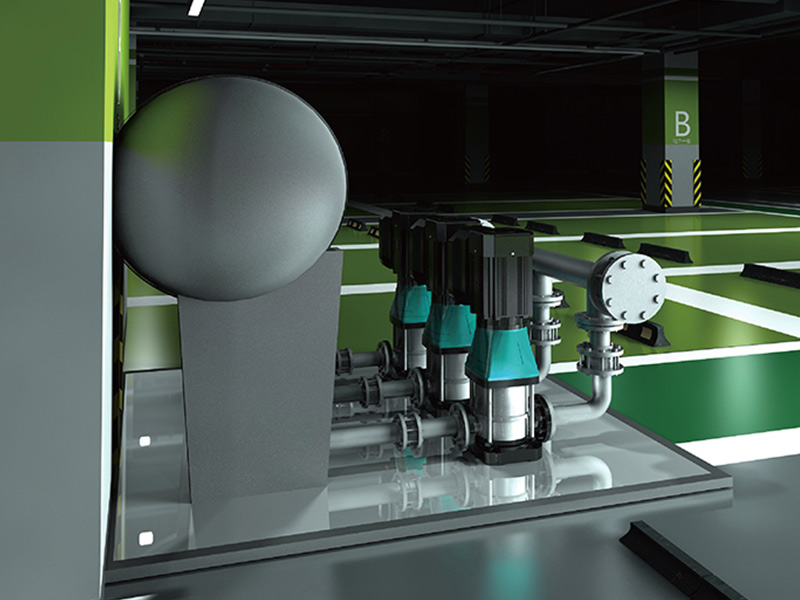

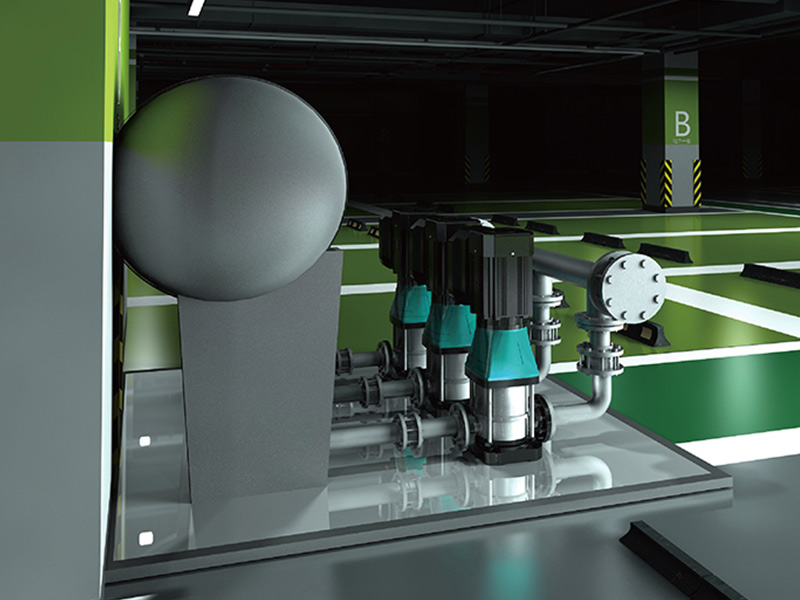

Integrating with Modern Control Systems

Permanent magnet circulation pumps can be paired with variable frequency drives and building automation systems to provide greater flexibility in operation. When combined with intelligent centrifugal pumps, this integration allows operators to monitor flow, pressure, and energy use from a central platform. Such monitoring helps identify inefficiencies early and supports predictive maintenance strategies. The synergy between intelligent control and permanent magnet efficiency strengthens the overall resilience and adaptability of commercial water systems.