Facility managers and engineers often compare the performance of an Intelligent Centrifugal Pump with that of a Pipeline Circulating Pump when evaluating options for long-term operation. While circulation pumps play an essential role in maintaining stable flow within heating, cooling, and domestic water systems, intelligent centrifugal pumps stand out for their ability to combine durability with smart control features. Understanding what contributes to their long service life helps users make informed decisions when investing in critical infrastructure.

Strong Motor Technology Reducing Mechanical Stress

One of the reasons intelligent centrifugal pumps achieve extended durability is the integration of permanent magnet motors combined with variable frequency drives. These motors operate with higher efficiency, generating less heat and mechanical strain on components. The variable frequency drive gradually ramps motor speed up or down during start and stop cycles, preventing sudden pressure surges that can damage bearings, shafts, or seals. Compared with pipeline circulating pumps that often run at a fixed speed, the intelligent version benefits from smoother operation, reducing wear over years of continuous service.

Advanced Control Systems Protecting Components

Intelligent centrifugal pumps incorporate monitoring systems that track pressure, temperature, and flow in real time. This monitoring allows the pump to adjust its performance to match actual system conditions. By avoiding excessive pressure or unnecessary operation at high speeds, the control system prevents premature stress on moving parts. A pipeline circulating pump ensures continuous water movement but typically does not adjust dynamically to varying conditions, making intelligent pumps more resilient under fluctuating demand.

High-Quality Construction for Demanding Environments

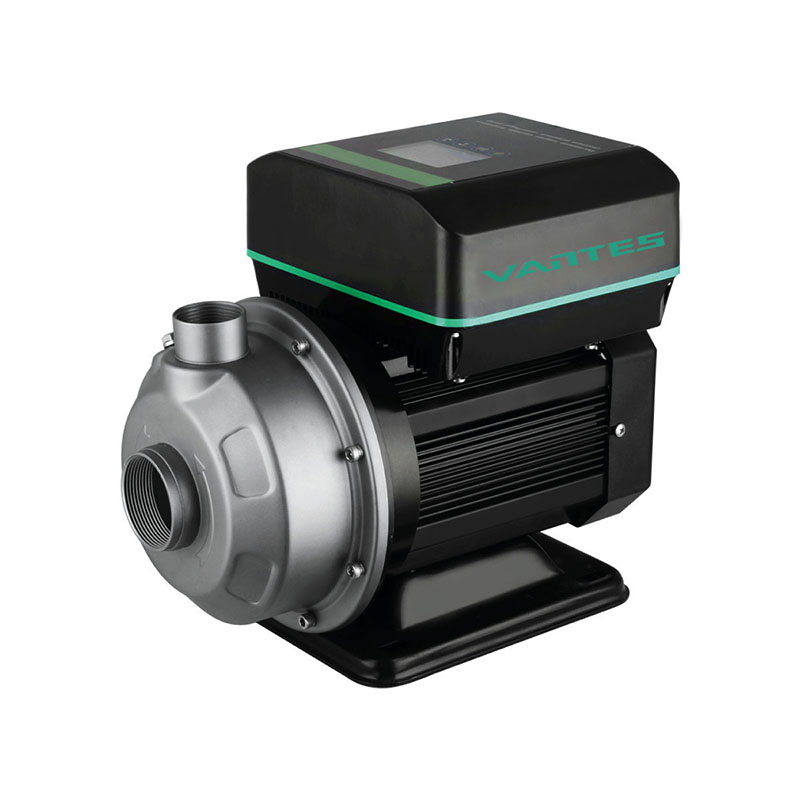

Durability also comes from the materials used in manufacturing. Intelligent centrifugal pumps are often constructed with corrosion-resistant alloys, reinforced impellers, and seals designed to withstand long-term exposure to varying water conditions. In commercial or industrial systems where pumps must operate continuously, these material choices reduce the likelihood of failures. While pipeline circulating pumps remain well-suited for closed-loop applications, intelligent centrifugal pumps are built to handle broader operating ranges, adding to their overall longevity.

Maintenance Features Supporting Long-Term Use

Ease of maintenance contributes to the durability of any pump. Intelligent centrifugal pumps are designed with user-friendly access points, intuitive interfaces, and remote monitoring capabilities that allow maintenance teams to identify issues early. Alerts and performance data help reduce unexpected downtime by ensuring timely interventions. Pipeline circulating pumps generally require less frequent adjustment due to their simpler operation, but intelligent centrifugal pumps extend their service life by actively reducing conditions that typically cause mechanical wear.

Reduce the effects of water hammer and vibration

Water hammer can create sudden pressure shocks that damage pipelines, valves, and pump components. In addition, the permanent magnet motor design reduces vibration, which helps extend the life of seals and bearings. These protective functions add resilience to the pump’s structure, ensuring that its performance remains stable in systems subject to variable demand.

Compatibility with Building and Industrial Systems

Another factor that supports durability is adaptability. Intelligent centrifugal pumps can be integrated with building automation systems or industrial control platforms, enabling better coordination across multiple devices. When combined with pipeline circulating pumps in complex facilities, the intelligent units handle variable demand while circulation pumps ensure stable base flow.

Sustaining Efficiency Over Time

Energy efficiency and durability are closely related. By consuming less power, generating less heat, and reducing unnecessary mechanical effort, intelligent centrifugal pumps sustain their performance over extended operational cycles. Reduced energy losses mean that the pump operates closer to its design specifications for a longer time, avoiding the gradual decline often seen in less efficient equipment. For operators, this results in a pump that not only saves energy but also continues to function consistently year after year.

Practical Considerations for Users

For facilities considering an investment in intelligent centrifugal pumps, evaluating installation requirements, expected duty cycles, and system compatibility is important. Proper sizing and integration ensure that the pump delivers its durability advantages without overstressing the system. Pairing it with pipeline circulating pumps where appropriate creates a balanced solution, combining adaptive pressure management with steady circulation.