In recent years, the Multi-Stage Centrifugal Pump has seen considerable advancements, becoming a key component in a wide range of industries. This versatile pump is primarily used for handling high-pressure applications, offering efficient performance across various sectors such as water treatment, oil and gas, chemical processing, and industrial manufacturing. By utilizing multiple impellers, the Multi-Stage Centrifugal Pump allows for enhanced fluid transfer efficiency, ensuring reliable operation even in demanding conditions.

The design of a Multi-Stage Centrifugal Pump involves stacking several impellers (or stages) in a single casing, enabling the pump to achieve higher pressures while maintaining relatively low flow rates. This configuration makes it ideal for situations where high head pressure is required, such as in municipal water systems, fire protection systems, and boiler feed applications. The ability to operate efficiently at different flow rates is a significant advantage, making these pumps an essential tool in both industrial and domestic sectors.

One of the key benefits of the Multi-Stage Centrifugal Pump is its versatility. In the chemical industry, for example, these pumps are used to transfer fluids that require precise pressure control and minimal pulsation. The pumping efficiency, combined with the ability to handle corrosive and abrasive liquids, makes the Multi-Stage Centrifugal Pump indispensable for this industry. In water treatment plants, these pumps help maintain consistent pressure levels throughout the filtration process, ensuring clean water is delivered to consumers.

The oil and gas industry also relies heavily on Multi-Stage Centrifugal Pumps for various applications, including crude oil transportation, water injection, and pressure boosting. These pumps are crucial for ensuring that pipelines maintain the appropriate pressure to facilitate the continuous movement of crude oil across vast distances. Their rugged construction and ability to handle both high pressure and varying fluid viscosities make them a fit for this highly demanding industry.

In the field of agriculture, the Multi-Stage Centrifugal Pump plays a vital role in irrigation systems, enabling the transportation of water over long distances. By utilizing multiple stages, these pumps provide the necessary pressure to move water through large networks of pipes to reach farms, ensuring crop growth. Furthermore, their energy-efficient design is critical in reducing operational costs for agricultural operations.

Another industry where Multi-Stage Centrifugal Pumps are making a significant impact is in the HVAC (heating, ventilation, and air conditioning) sector. These pumps are used in large-scale systems to circulate water for cooling and heating, ensuring that temperature control remains consistent across buildings and facilities. Their ability to operate at variable speeds also offers flexibility in managing different system demands, improving overall energy efficiency.

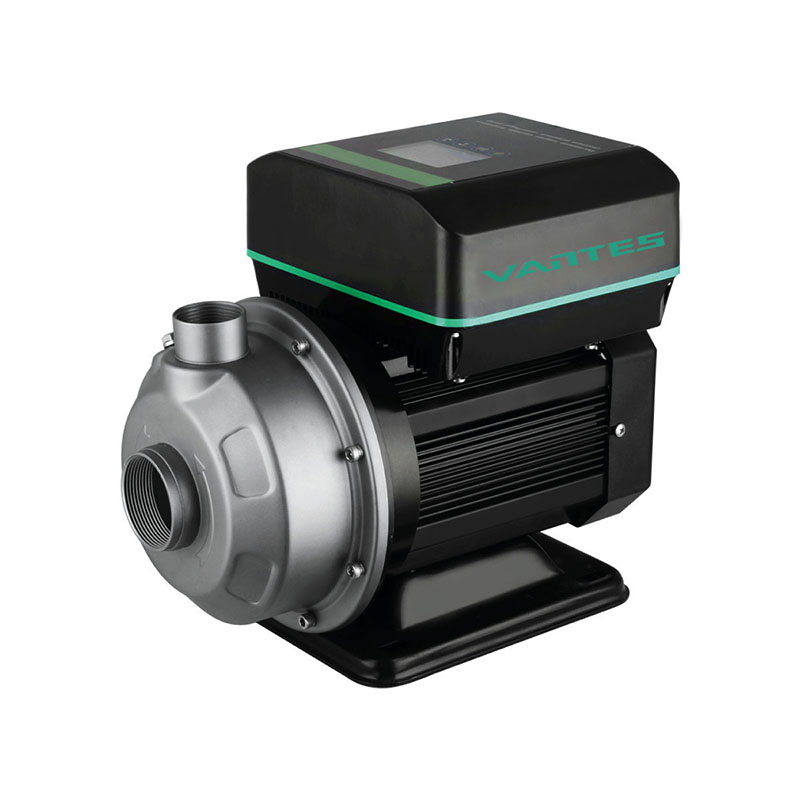

Technological advancements in the design of the Multi-Stage Centrifugal Pump have further improved its performance. Modern pumps are equipped with variable speed drives (VSDs), which allow for greater control over flow rates and pressure settings. This technology not only enhances the operational efficiency of the pump but also reduces energy consumption, to significant cost savings over time.

The integration of intelligent monitoring systems in the Multi-Stage Centrifugal Pump has also become a major trend in recent years. These systems can track various parameters such as temperature, vibration, and pressure, alerting operators to any potential issues before they become critical. Predictive maintenance, powered by real-time data, helps prevent unplanned downtime, reducing maintenance costs and improving the lifespan of the pump.

As industries continue to evolve, the demand for Multi-Stage Centrifugal Pumps is expected to grow. The push for sustainable and energy-efficient solutions is driving innovations in pump technology, with manufacturers focusing on improving efficiency, reducing emissions, and enhancing durability. The future of Multi-Stage Centrifugal Pumps looks promising, as industries continue to rely on this essential equipment for handling high-pressure fluid transfer.

Moreover, the rise of smart technologies and automation in industries is likely to further integrate the Multi-Stage Centrifugal Pump into digital ecosystems. Pumps will increasingly be connected to cloud-based platforms, enabling operators to monitor performance remotely, schedule maintenance, and optimize the pump's operation in real time. This shift towards smarter, more connected systems is not only improving the operational efficiency of pumps but is also contributing to the overall digitization of industrial operations.