As Europe intensifies its focus on sustainability and environmental protection, industries across the continent are adopting innovative technologies that contribute to energy savings, waste reduction, and better resource management. One such technology gaining traction is the vertical centrifugal pump. These pumps, designed to move water or other fluids efficiently through a system, have become increasingly popular in Europe due to their exceptional environmental and sustainability credentials. Their ability to provide high performance with minimal environmental impact has made vertical centrifugal pumps a hot commodity in various industries, from municipal water systems to industrial applications.

What Are Vertical Centrifugal Pumps?

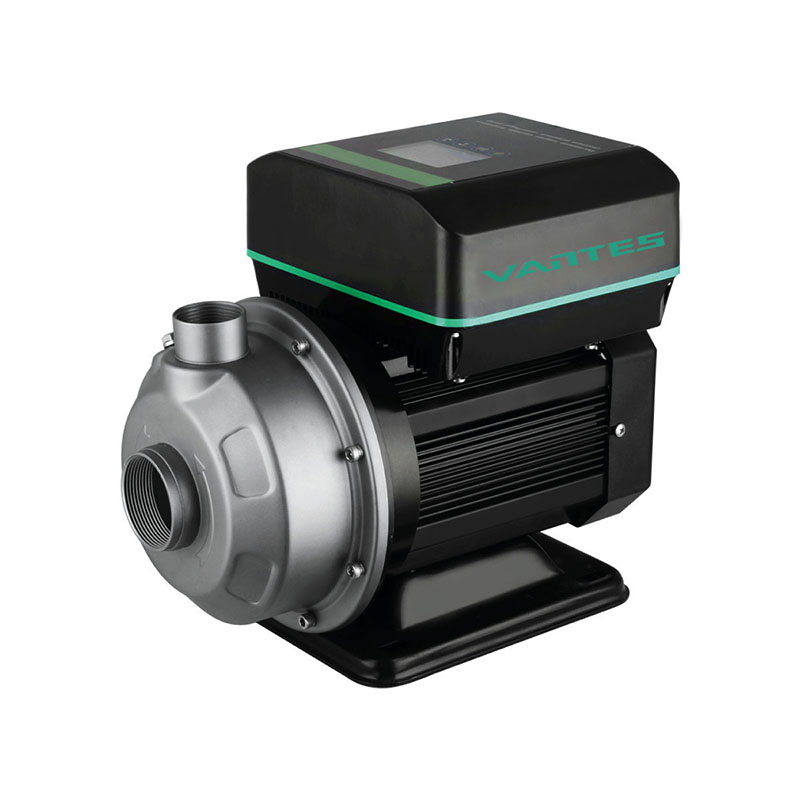

Vertical centrifugal pumps are a type of pump that use a rotating impeller to move water or other fluids vertically, typically within a well or vertical pipeline system. These pumps are commonly used in a variety of applications, including water treatment facilities, HVAC systems, irrigation systems, and industrial processes, particularly where high vertical lift and compact designs are required. Their ability to handle large volumes of fluid with minimal power consumption makes them ideal for scenarios where energy efficiency is a priority.

Unlike traditional horizontal pumps, vertical centrifugal pumps take up less space and offer a more streamlined design. Their energy efficiency, robust construction, and ability to perform under conditions make them an attractive option for both new installations and upgrades in existing systems.

The Surge in Popularity of Vertical Centrifugal Pumps in Europe

Europe has long been at the forefront of environmental protection and sustainability initiatives. With ambitious goals to reduce carbon emissions, conserve water, and promote energy-efficient technologies, the European market is ripe for the adoption of products that support these objectives. Vertical centrifugal pumps, with their numerous benefits for both energy efficiency and long-term sustainability, are gaining considerable attention from a wide range of sectors, including utilities, agriculture, manufacturing, and building services.

Several factors are contributing to the increasing demand for vertical centrifugal pumps in Europe:

1. Energy Efficiency and Reduced Carbon Footprint

As Europe strives to meet its carbon neutrality goals, energy-efficient solutions are in high demand. Vertical centrifugal pumps are specifically designed to optimize power consumption. They operate with high hydraulic efficiency, reducing the amount of energy required to move water or other fluids through the system. This translates into significant cost savings for businesses, municipalities, and industries looking to reduce their energy bills while also lowering their carbon footprint.

A key feature of modern vertical centrifugal pumps is the use of advanced motor technology, such as variable frequency drives (VFDs), which allow the pump speed to be adjusted according to real-time demand. By matching the pump speed to the system’s requirements, vertical centrifugal pumps avoid wasting energy, ensuring that they run only as fast as necessary. This smart, demand-driven operation makes them an ideal choice for Europe’s sustainability-driven industries.

2. Water Conservation and Efficient Fluid Management

Water scarcity is a growing concern in many European regions, and industries are under increasing pressure to implement water-efficient solutions. Vertical centrifugal pumps help optimize the flow of water or fluids through complex systems, ensuring that water is used as efficiently as possible. In applications such as irrigation, water treatment, and building cooling systems, these pumps can reduce water waste by maintaining a steady flow of water under consistent pressure, ensuring use at every stage of the process.

For example, in irrigation systems, vertical centrifugal pumps can be used to ensure that water is distributed precisely where it is needed, preventing the overuse of water and maximizing crop yields. In industrial processes, these pumps can be integrated into closed-loop water systems, allowing water to be reused multiple times before needing to be replaced or replenished, further conserving water resources.