Variable frequency pumps (VFPs) have become an indispensable part of modern industrial applications due to their efficiency, precision, and energy-saving capabilities. These pumps are particularly valued for their ability to adjust the speed of the motor, ensuring that the pump operates only at the necessary flow rate, thus reducing energy consumption. However, like all mechanical systems, variable frequency pumps require regular maintenance to ensure their continued performance and longevity. This article explores key strategies for maintaining variable frequency pumps to prevent costly breakdowns and optimize their efficiency.

Understanding Variable Frequency Pumps

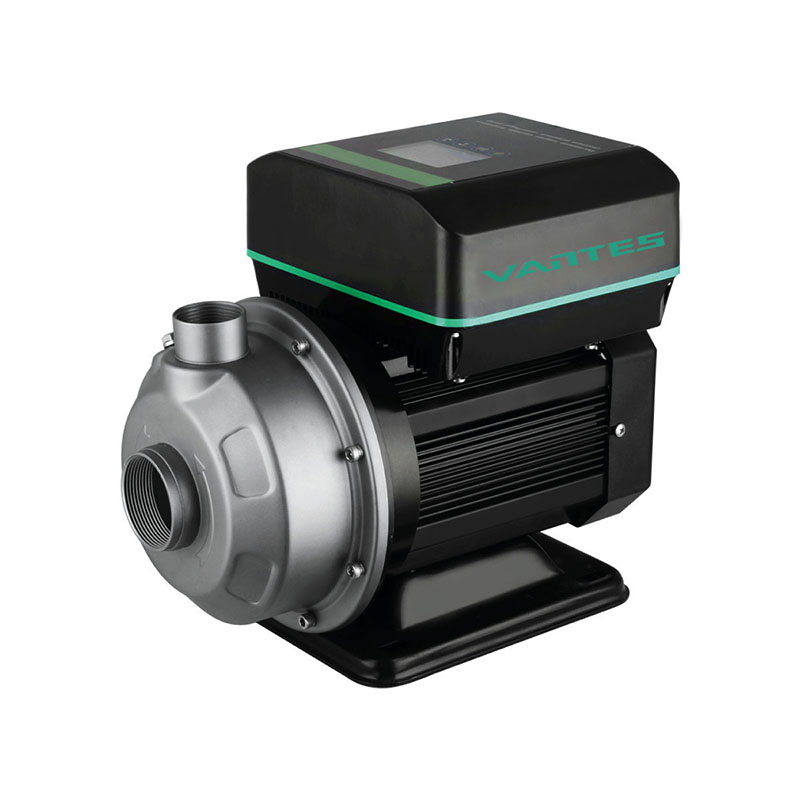

A variable frequency pump is a type of pump that uses a variable frequency drive (VFD) to control the motor speed. By adjusting the frequency of the electrical power supplied to the pump’s motor, the speed of the pump can be varied. This allows the pump to meet changing demands in real-time without running at full capacity all the time. Variable frequency pumps are commonly used in applications such as HVAC systems, water treatment plants, and industrial processes where flow rate and pressure need to be carefully controlled.

The Importance of Regular Maintenance

Regular maintenance of variable frequency pumps is essential to ensure that they operate efficiently, minimize downtime, and extend their lifespan. A lack of proper maintenance can lead to issues such as reduced performance, higher energy costs, and premature failure of the pump or its components. To avoid these problems, it is important to establish a routine maintenance schedule that addresses both the mechanical and electrical components of the pump system.

Monitoring and Cleaning the Pump

One of the steps in maintaining variable frequency pumps is ensuring that the pump itself is clean and free of debris. Over time, dirt, dust, and contaminants can accumulate within the pump and obstruct its components. This can reduce the efficiency of the pump and lead to overheating or other mechanical issues. Regularly inspecting the pump’s interior for any build-up of dirt or sediment is crucial.

Cleaning the pump’s components is also important to prevent corrosion and damage. The motor and the pump housing should be wiped down periodically to remove any buildup of oils, dust, or moisture that may have accumulated during operation. If the pump is used in a water treatment application or in environments where chemical exposure is common, specialized cleaning agents may be necessary to remove any hazardous residues that can impact the pump’s performance.

Inspecting the Motor and Variable Frequency Drive (VFD)

The motor and the variable frequency drive (VFD) are the heart of a variable frequency pump. The VFD controls the speed and operation of the motor by adjusting the electrical frequency, making it essential to the pump’s energy-saving capabilities. Over time, the motor’s bearings and other components may wear down, causing inefficiencies or mechanical failure.

Regularly checking the motor’s bearings for signs of wear or vibration is an important step in identifying potential issues before they become major problems. Additionally, checking the motor’s alignment and ensuring that it is securely mounted within the pump system is essential for maintaining stability and preventing unnecessary wear.

The variable frequency drive also requires routine inspections to ensure that it is operating properly. Look for signs of overheating, unusual noise, or irregular output from the VFD. If the VFD is showing any signs of malfunction, it is important to address these issues immediately to prevent damage to the motor or other components.

Lubrication and Fluid Levels

Proper lubrication is essential for the smooth operation of a variable frequency pump. The motor bearings, shaft, and other moving parts need to be adequately lubricated to reduce friction and prevent overheating. Over time, lubrication can degrade or become contaminated, so it is important to regularly check and replace the lubricating oil or grease.

Similarly, checking the fluid levels in the pump is essential. If the pump is running low on fluid, it may struggle to maintain the required pressure or flow rate, leading to increased wear and potential damage. Keep an eye on fluid levels and top them up as needed to keep the pump running smoothly.

Electrical System Checks

The electrical components of variable frequency pumps are critical to their performance. A malfunction in the electrical system, such as a short circuit, damaged wiring, or a failed capacitor, can significantly impact the pump’s operation. Regularly inspecting the electrical connections and components for signs of wear or damage is crucial.